APPLICATIONS

OIL & GAS EXTRACTION

Stainless and Nickel alloys provide heat and corrosion-resistant solutions for onshore and offshore extraction. Nickel based alloys from ranges stocked by SNAPP and Nickel Piping Products are ideal for cost-effective manufacture of pumps, valves and process control equipment, in addition to extraction and processing.

CHEMICAL & PROCESS INDUSTRIES

These industries require high-performance, high-grade alloys which can withstand being subjected to the highest levels of chemical and processing abuse. Stainless, and especially nickel alloys are known for their resistance to corrosion and fatigue in conditions presenting high temperatures and caustic media. SNAPP and Nickel Piping Products supplies many alloys, which are chosen for their corrosion-resistant properties in process applications, and are ideal for heat exchangers, furnaces, piping, pumps and valves.

MARINE ENGINEERING

Nickel-based alloys are oxidation and corrosion resistant and well-suited for service in extreme environments presented in the marine industry. Sea water applications use nickel alloys for offshore platforms, as well as in power and process plants that use seawater as coolant. Other uses include wire rope, propeller blades, propulsion motors and sheathing for undersea communication cables. Known for their ability to withstand severe conditions, our alloys are proven to reduce long range costs by providing reliable and durable solutions for the marine industry.

POWER GENERATION

An outstanding balance of strength, temperature, and defect tolerance characteristics makes ranges of SNAPP’s stock ideal in a wide range of power generation applications. Excellent mechanical properties at extremely low and extremely high temperatures, in addition to outstanding resistance to pitting and corrosion has led stainless and nickel-based alloys be used in stressful applications presented by the power generation industry including components such as discs, shafts and blades, tanks, piping, heat exchangers, pumps and valves.

FOOD PRODUCTION

304 and 316 grades are the most commonly used stainless steel in food production and storage. Stainless steel allows for faster cleaning and passes no taste to the food that it comes in contact with. In addition, excellent mechanical properties at extremely low and extremely high temperatures makes these alloys a versatile choice for food production.

CONSTRUCTION & BUILDING

Stainless steel-based alloys provide a low maintenance cost for cladding, handrails, roofing, drainage, wall supports, and structural applications. Corrosion resistance and aesthetic appearance make stainless steel a perfect solution for architecture, building, and construction.

MEDICAL APPLICATIONS

Mainly due to its ease of cleaning, hygienic nature, corrosion and rust resistance and durability, stainless steel is commonly used in the medical field for tools, machines, syringes, probes, and even medical implants. These characteristics makes ranges of SNAPP’s stock ideal in a wide range of medical applications.

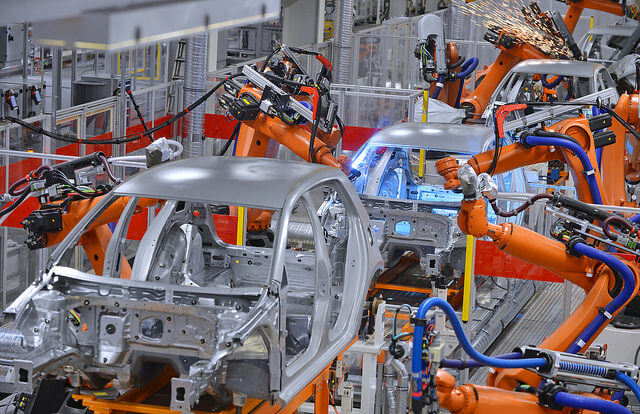

AUTOMOTIVE INDUSTRY

Cars are making increasing use of stainless steel in structural applications, exhaust systems, and other parts. Stainless Steel helps achieve low long term maintenance costs and less impact on the environment.

AEROSPACE ENGINEERING

Nickel Alloys are widely used in the aerospace industry due to their resistance to oxidation and corrosion and strong performance under high stress conditions. Many of the alloys stocked by Nickel Piping Products are proven to reduce your long range costs by providing reliable and durable solutions for the Aerospace Industry.